Atlantic Concrete Association wins Leadership Award

The Atlantic Concrete Association is thrilled to report that we have won the Leadership Award from the Construction Safety Association NS for our work with the new Certification Driver Professional online Course! Great job to the dedicated volunteers who were responsible for making this happen!

ACA Donates to the IWK in 2019 - Instead of gifts for the 2019 ConAtlantic speakers, This year the ConAtlantic committee decided to donate $500 to the IWK Mental Health Intiaitives for children in need.

ACA Donates to the IWK in 2017

Had a great time with the ladies and gentlemen of the IWK Foundation. This year ACA donated $500 toward mental health initiatives for children.

This House on Mexico Beach survived Hurricane Michale. That's no Coincidence.

ACA Donates to the IWK in 2017

In keeping with a new tradition started in 2016, the Atlantic Concrete Association is thrilled to announce it recently made a $500 donation to the IWK Foundation. The donation is earmarked for the Child Life Department of Christmas Needs program helping children while staying at the IWK during the holidays. ACA Executive Director, Pam Woodman is shown presenting ACA's contribution along with the amazing staff at the IWK Foundation!

Industry takes exception to wood claims

By Kathy Johnson

With construction slated to start in downtown Dartmouth of Atlantic Canada’s first six-storey wood frame building, the Atlantic Concrete Association (ACA) and the Cement Association of Canada (CAC) are expressing concern and taking exception to claims that midrise wood constructed buildings offer lower project costs, shorter construction timelines and increased sustainability than other building materials, including concrete.

“This innovative, mixed occupancy building will be Atlantic Canada’s first modern six-storey wood building. In recent years, midrise wood construction has been embraced by jurisdictions across Canada for the many advantages it delivers, including lower project costs, shorter construction timelines and increased sustainability,” says Atlantic Wood Works project coordinator Patrick Crabbe in an early September press release announcing the project.

Not the case, says the ACA. When it comes to sustain-ability, a study conducted by the National Ready-Mixed Concrete Association and reported by the World Business Council for Sustainable Development says it takes less energy to produce concrete than it does to produce steel or wood. The ACA is currently de-veloping a position statement responding to the wood industry’s initiative, which will be available on its website early next year.

“The production of cement — the primary in-gredient of concrete — is responsible for 1.5 per cent of Canada’s CO2 emissions, compared with three per cent for the forest industry,” the report says. “Given the costs and challenges of shipping concrete, most concrete is produced very close to where it will be used. This reduces the need for fuel for transportation.

“Concrete is highly reflective. A high percent-age of the light that hits concrete roads and walls is reflected, thereby helping to keep cities cooler and reduce the need for air conditioning. Heat moves very slowly through concrete walls and floors, thereby reducing swings in indoor temperatures.

“The industry increasingly uses waste prod-ucts to replace some of the conventional cement required in the production of concrete. The concrete industry has made important progress in its use of alternative fuels. The longevity and stability of concrete means it requires less maintenance and it’s rarely replaced.”

The benefits of building with concrete include: the lowest carbon footprint for a structure or pavement over its lifecycle; unparalleled strength, durability, longevity and resilience; maximized energy efficiency via thermal mass; durability in any environment; a building material that doesn’t burn, rust or rot; safety and security; versatility (it can be moulded into any shape, colour or pat-tern imaginable); no off-gas; excellent vibration and sound insulating; low maintenance costs; and 100 per cent recyclability. (Source: http://www.re-discoverconcrete.ca/lifecycle-performance-at-the-heart-of-a-substance-low-carbon-future/a-better-building-material/the-benefits-of-concrete)

“Plus the materials needed to make concrete are abundant in just about every locale on the planet. It’s quite simply the most versatile build-ing material on earth,” the report says.

For the CAC, “One of issues that irks us,” about mid-rise wood construction is “many are being built as sacrificial buildings,” says Rick McGrath, CAC’s director of codes and standards. “The only rationale that applies is, in the event of a fire, everyone can get out safely. The only design requirement is get everybody out safely before it burns. Our rationale has been to build for the long run and stand the test of time. We should be build-ing stronger and longer, not weaker and cheaper.”

As it is, the midrise wood buildings being con-structed are “best described as hybrid buildings,” says CAC’s Adam Auer, noting although there may be more wood used than in a traditional wood build, concrete is still playing a foundational and structural role.

Auer says in Europe, the building codes and standards for mid-rise wood structures are much more stringent than the requirements in Canada. For example, in Europe all exposed wood must be protected from the elements, so that adds quite a bit to the cost.

“I expect as people become more aware of this type of construction, there will be a call for better regulations,” Auer says.

The IWK Foundation thanks DecementFest

On December 5th, the Atlantic Concrete Association hosted its 7th annual DecementFest at the Garrison Brewery in downtown Halifax. Each year ACA members and invited guests get together for a little entertainment and socializing to kick off the holiday season. To celebrate this year, ACA donated $500 to the IWK Foundation for the Child Life Department for Christmas Needs program to help children during the holidays at the IWK.

Photo: Pam Woodman (ACA, Executive Director) Daisy Dobden (Assist to Philanthropy & Communications, IWK Foundation) & Scott Flemming (ACA President & Ocean Contractors Limited)

Atlantic Concrete Association accepts CANS Bowman Award

Pam Woodman, Executive Director of the ACA, accepts a Bowman Award during ceremonies on October 1. in Digby NS. The award is presented each year by the Construction Association of NS (CANS) to recognize companies that have held continous membership for more than 25 years. The award is named after Earle Bowman of Fundy Construction, a past president and honourary life memebr. To honour the efforts and grand achievements of this prolific mover and shaker in the construction industry, companies are awarded for their years of membership and displaying a degree of dedication that would make Earl Bowman proud.

Photo: Pam Woodman (ACA, Executive Director) accepting Bowman Award on behalf of ACA.

2026 ConAtlantic & Annual General Meeting!!!

ConAtlantic will be hosting its 2026 in St. John's NL!

ConAtlantic will be hosting its 2026 in St. John's NL!

Each year members of the ACA (The Atlantic Concrete Association) come together for professional development, technical workshops and networking opportunities and to help discuss ways of continuously improving the growth and success of our industry! ConAtlantic provides educational and social initiatives while contributing to the professional development of our members.

Our next ConAtlantic will be hosted in St. John's NL in 2026! Book your rooms.

Registration Opening Soon!

Please Note: Concrete Atlantic is not responsible for content information

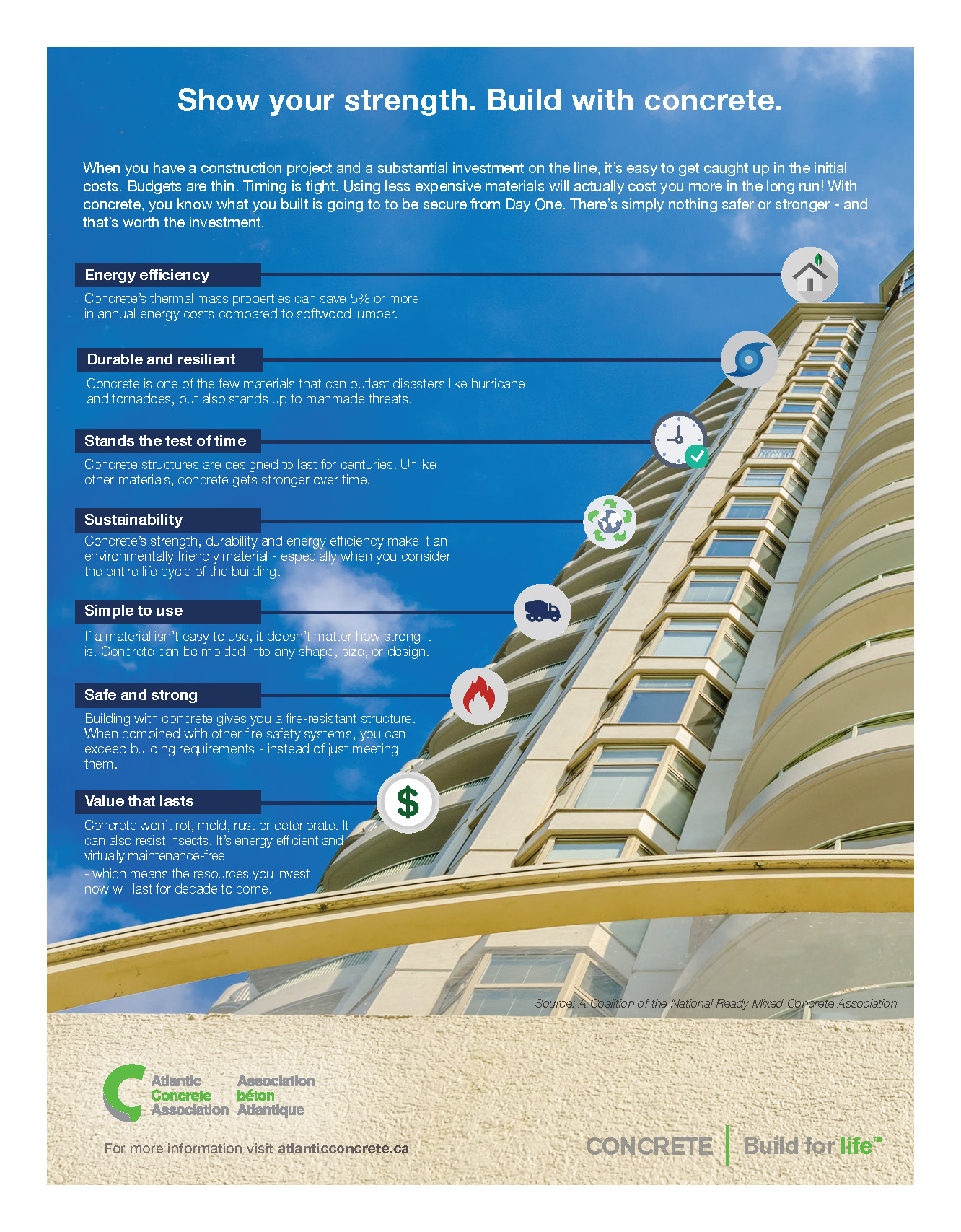

When you have a construction project and a substantial investment on the line, it’s easy to get caught up in the initial costs. Budgets are thin. Timing is tight. Using less expensive materials will actually cost you more in the long run! With concrete, you know what you build is going to to be secure from Day One. There’s simply nothing safer or stronger - and that’s worth the investment.

Energy efficiency - Concrete’s thermal mass properties can save 5% or more in annual energy costs compared to softwood lumber.

Durable and resilient - Concrete is one of the few materials that can outlast disasters like hurricane and tornadoes, but also stands up to manmade threats.

Stands the test of time - Concrete structures are designed to last for centuries. Unlike other materials, concrete gets stronger over time.

Sustainability - Concrete’s strength, durability and energy efficiency make it an environmentally friendly material - especially when you consider the entire life cycle of the building.

Simple to use - If a material isn’t easy to use, it doesn’t matter how strong it is. Concrete can be molded into any shape, size, or design.

Safe and strong - Building with concrete gives you a fire-resistant structure. When combined with other fire safety systems, you can exceed building requirements - instead of just meeting them.

Value that lasts - Concrete won’t rot, mold, rust or deteriorate. It can also resist insects. It’s energy efficient and virtually maintenance-free - which means the resources you invest now will last for decade to come.

DOING OUR PART TO REDUCE GHGS

Cement production enjoys a relatively small footprint on many environmental metrics, however, it is energy and CO2 intensive. While cement is only a small component of a typical concrete mix, the cement sector is nonetheless deeply committed to reducing its GHGs and has made significant investments to that end.

In the last twenty years, we have reduced the energy required to make a tonne of cement by about 20%. Today, we are focusing on bringing lower carbon cements to market through a variety of strategies:

- Our recently introduced lower carbon cement Contempra reduces CO2 emissions by 10% compared to regular cement. If Contempra were to replace all cement consumed in Canada, it would save almost 1MT of GHG emissions per year;

- Substituting traditional fossil fuels, including coal, with lower carbon alternatives has the potential to yield significant GHG reductions across Canada. In leading jurisdictions, some cement facilities have achieved carbon intensity reductions of over 50% in the fuels they use; and,

- We are making deep investments in potentially transformative technologies such as carbon capture and reuse to transform concrete into a “carbon sink”.

SUSTAINABLE CONCRETE!

Building our communities in the age of climate change

The weather was once the worry of only farmers and parents dressing children for school. Today, climate change makes front page and business headlines. Stories of recent natural disasters and their impact on our economies have heightened everyone’s concern − and rightly so.

A 2011 United Nations report on disaster risk reduction identified that losses from disasters are rising faster than gains made through economic growth across many regions.

In Canada, the National Roundtable on the Environment and the Economy (NRTEE) predicted that by 2020, climate change impacts could cost the Canadian economy up to 1% of Gross Domestic Product (GDP), or $5 billion per year. That cost could climb to $43 billion per year by 2050. If 2013 was any indication, these predictions appear accurate. According to the Insurance Bureau of Canada, 2013 was the most expensive year on record for insurable losses in Canada, with $3.2 billion in weather-related claims. The 2013 Calgary flood alone is estimated to have cost upwards of $6 billion, including non-insurable losses.

A 2012 report from the Insurance Bureau of Canada stated that “climate change is likely responsible for the rising frequency and severity of extreme weather events, such as floods, storms, droughts and fires since warmer temperatures tend to produce more violent weather patterns.”

The scientific research indicates that our climate will continue to change, with rising temperatures and sea levels, fluctuating rainfall and snowfall patterns, and more unpredictable extremes ranging from floods to droughts and freezing winters. The certainty of that reality has a direct impact on how we define and grapple with the concept of sustainability.

While sustainability is most commonly understood in terms of reducing the immediate impact of human activity on the environment, climate change and other environmental and social pressures are illustrating that sustainability is an even more complex goal as we search for solutions responsive to a dynamic and changing world. As we strive to reduce greenhouse gases (GHGs) for example, we must also prepare for a world of more uncertain weather extremes wrought by changes to our climate that are by now inevitable.

Concrete thoughts:

- It takes less energy to produce concrete than it does to produce steel or wood according to a study conducted by the National Ready-Mixed Concrete Association and reported by the World Business Council for Sustainable Development.

- The production of cement – the primary ingredient of concrete – is responsible for 1.5% of Canada’s CO2 emissions, compared with 3% for the forest industry.

- Given the costs and challenges of shipping concrete, most concrete is produced very close to where it will be used. This reduces the need for fuel for transportation.

- Concrete is highly reflective. A high percentage of the light that hits concrete roads and walls is reflected, thereby helping to keep cities cooler and reduce the need for air conditioning.

- Heat moves very slowly through concretewalls and floors, thereby reducing swing in indoor temperatures.

- The industry increasingly uses waste products to the replace some of the conventional cement required in the production of concrete.

- The concrete industry has made important progress in its use of alternative fuels.

- The longevity and stability of concrete means that it requires less maintenance and it is rarely replaced.

For more information on the environmental benefits of concrete, please visit the Rediscovery Concrete website.

Environmental Product Declaration Document for Canadian Ready-Mixed Concrete

LEED® AND ENVIRONMENTAL PRODUCT DECLARATIONS

Since its inception, the LEED® green building program has been used to reduced environmental impacts of the built environment. LEED® has been a market transformation device affecting all sectors of the construction industry, including concrete production and construction.

The system is based on four certification levels (certified, silver, gold and platinum), allowing projects to earn points for environmentally friendly strategies employed during the design and construction process. Because of concrete’s versatility there are many applications where concrete can be used in a building project, from foundation and superstructure to sidewalks and parking lots. That means concrete can contribute to every credit category.

An Environmental Product Declaration (EPD) for building materials can earn your products valuable credits within the LEED® green building program meet a growing number of procurement requirements for governments and industry. Concrete is an important component of these credits. Using concrete can influence 25 of the 55 LEED® V4 credits and prerequisities and potentially contribute to as many as 74 of the 110 points available. Download the EPD document

Detailed information on the LEED® v4 and project certification process is available at www.usgbc.org or www.nrmca.org/sustainability or cagbc.org.

Environmental Product Declaration

Download the EPD document Document for Canadian Ready-Mixed Concrete

THINGS TO CONSIDER WITH CONCRETE

STRONG, DURABLE, AND LOW MAINTENANCE

Concrete products last decades longer than alternative building materials. Not only is concrete’s structural stability maintained for longer periods, it is non-combustible, preventing the spread of fire from one unit or one building to another. It is resistant to moisture and doesn’t rot or mold. And it is sufficiently strong to resist impacts, blasts and natural catastrophes like earthquakes, tornadoes and floods.

ENERGY-EFFICIENT

The ability of concrete products to store energy (their thermal mass) helps moderate interior temperature conditions, allowing a more constant temperature both in cold and hot regions. It improves a building’s “passive survivability” in the event that services such as power, heating fuel, or water are lost — minimizing energy demands for the city as a whole and reducing the GHG emissions from heating and cooling energy.

COMFORTABLE

Concrete products have intrinsic properties of acoustic insulation. This can help amplify sound within a space or dampen it between spaces. Concrete buildings can measurably reduce sound transmission between residential units, giving occupants more privacy.

EMISSION-FREE

An inert substance when cured, concrete is emission-free and will not emit any gas, toxic compounds or volatile organic compounds.

VERSATILE

While strong and functional when hardened, concrete’s plasticity when freshly mixed lets designers adapt it to whatever form, shape, surface and texture they can imagine. Innovations such as ultra-high performance concrete, photocatalytic concrete and pervious concrete are also enabling new and creative uses.

IDEAL FOR ADAPTIVE REUSE

Because of concrete’s strength, sound attenuation, and fire resistance, concrete buildings can easily be converted to other occupancy types during their service life. Reusing buildings in this way can help limit urban sprawl and further contributes to the conservation of our resources and preservation of the environment.

COST-EFFECTIVE

Thanks to their durability, resilience, low maintenance requirements and energy-efficiency, structures built with concrete products reduce operating costs related to operational energy consumption, maintenance, and rebuilding following disasters. Insurance costs for concrete buildings during the construction and operating phases have also been shown to be significantly lower than for buildings constructed with combustible, moisture-sensitive materials.

100% RECYCLABLE

Concrete products can be recycled as aggregate — for use as sub-base material in roadbeds and parking lots, for gabion walls, as riprap to protect shorelines or in other applications — or as granular material, thereby reducing the amount of material that is landfilled and the need for virgin materials in new construction.

PRODUCED LOCALLY

Concrete is typically manufactured within 160 kilometers of a project site, using local resources. This greatly minimizes shipping and pollution and makes a significant contribution to the local economy.